Iron and Steel Today

Today,

there is an active iron and steel industry in Birmingham and the north

Alabama. U S Steel Corporation, USX, operates the Fairfield Works, with a

plate and tube mill. This is a fully integrated steel making mill, that

starts with raw materials and delivers finished steel plate and tubes.

Today,

there is an active iron and steel industry in Birmingham and the north

Alabama. U S Steel Corporation, USX, operates the Fairfield Works, with a

plate and tube mill. This is a fully integrated steel making mill, that

starts with raw materials and delivers finished steel plate and tubes.

For a great description of how a steel mill works, and what the parts of the mill are, see this link from the American Iron and Steel Institute, AISI, Learning Center.

The iron ore no longer comes from Red Mountain, rather it is delivered by barge to Birmingport, Alabama, on the Warrior River in West Jefferson County. The Birmingham Southern Railroad delivers the iron ore, actually pellets of pre processed material, called taconite, to the mill at Fairfield, located along I-20/59 several miles southwest of downtown Birmingham.

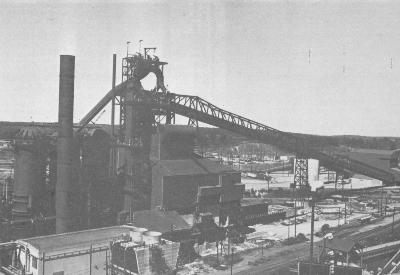

This photo, taken from Bennett, Old Tannehill, p. 128, shows the current No. 8 Blast Furnace at Fairfield, which is the only active USX furnace today. The entire plant covers many acres along the interstate.

There are several "mini-mills" located in Birmingham which utilize scrap steel and electric furnaces to make new products. This link can provide more information about Birmingham Mini Mills, from Birmingham's SMI Steel company.

At Decatur, Alabama, a new facility was brought on line in the late 1990's, TriCo Steel. This facility has received a great deal of press, and a certain amount of criticism since the State of Alabama used public funds as an inducement package to lure TriCo to come to Alabama.

At Gadsden, Gulf States Steel operated a fully integrated mill, which is a former Republic property. Gulf States closed this facility in the late 1990's. This closing seems to be driven by the age of the facility, in spite of upgrade investments, the "dumping" of Japanese steel on the U S market, and competition from other newer facilities, ironically, such as Trico at Decatur, which received incentives from the State to open a new plant. There has been a lot in the news in about steel tariffs being lifted in late 2003.

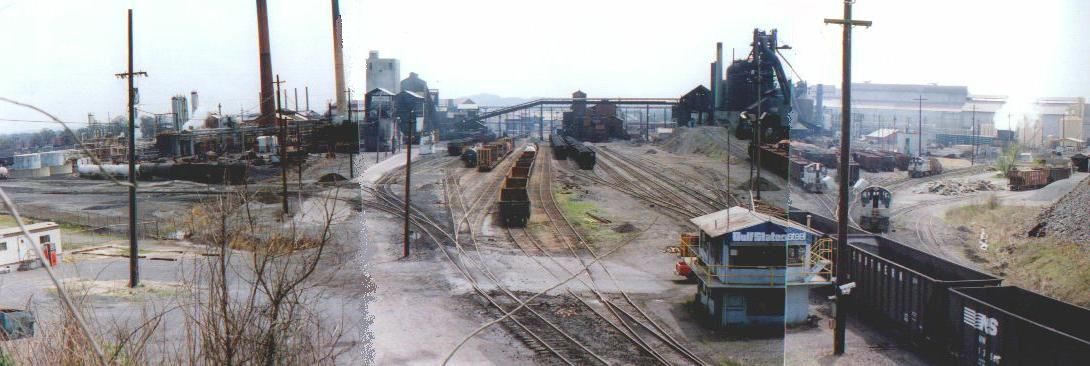

Looking at the industry in abstract, rather than the harsh light of international markets and accountants, its still a pretty good show to watch. The facility at Gadsden was easily viewed from a relatively safe vantage point along a highway overpass. The danger here is the traffic, not the mill itself. Here is a view of that facility, and the railroading here is front and center.

This view shows a set of spliced photos taken by the author, about 1995 from the overpass above the rail tracks. The blast furnace is at the right, and the coke plant is to the left of the tracks. To the far left is the chemical recovery plant that recovers materials driven off when coal is burned to make coke. In the rear, to the right, I believe is the rest of the mill where products are formed and fabricated. The locomotives here are lettered for Gulf States, and switch the yard which is located behind the camera. The day these were taken was also the day for a scheduled model railroad show in Attalla, nearby. Some days are just better than others!