Sloss Furnace

Sloss

Furnace is a museum piece. Shut down in 1970 when it was no longer

profitable for parent company U. S. Pipe, the property was donated to the City

and is maintained as a museum, and a monument to Birmingham's iron

industry. Sloss Furnace today is a fascinating place to visit, and a great

way to gain an understanding of the making of iron that was such a key element

in the development of the Magic City.

Sloss

Furnace is a museum piece. Shut down in 1970 when it was no longer

profitable for parent company U. S. Pipe, the property was donated to the City

and is maintained as a museum, and a monument to Birmingham's iron

industry. Sloss Furnace today is a fascinating place to visit, and a great

way to gain an understanding of the making of iron that was such a key element

in the development of the Magic City.

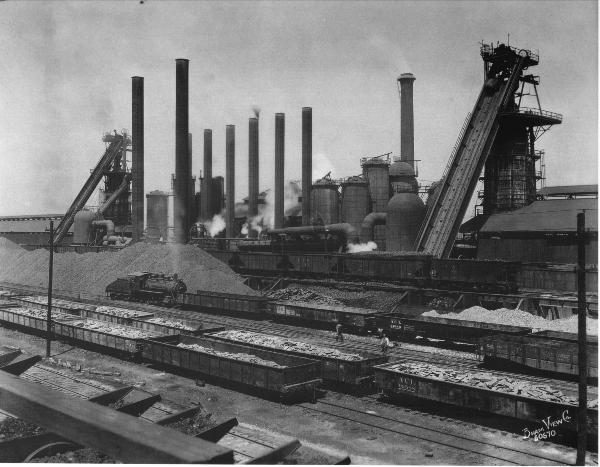

This photo, reproduced from the Birmingham Historical Society's book, Birmingham View, shows the "City furnace" as it operated from about 1929, when it was completely rebuilt, to 1970 when it closed.

The view is looking to the northwest, across the mainline tracks of the "railroad reservation". The switch engine, or shifter, operated by the Sloss, Sheffield, Steel and Iron Railroad (SSS&I) appears to be switching gondola cars loaded with pig iron bars.

How does a blast furnace work? Try this link to the AISI Learning Center -- several good graphics and lots of text.

In the background of the photo at the top of this page are the twin blast furnaces with their sloping charging hoist. The round top towers are known as stoves, and are used to heat gases that are part of the process. The shed structures at the left and right are the casting sheds, where workers directed the molten iron into sand molds laid out on the floor of the shed.

In later years, Sloss operated an automatic casting machine, which was located outside this view to the right. The molten iron was transferred to the casting machine in a "bottle" car. This is an special rail car with a large container, lined with refractory (special fire brick), so that the molten metal remains molten for a period of time. The container ("ladle or bottle") could be tipped to pour the molten material out for the desired purpose. This one, like many of these cars, was manufactured by the Schnabel Company, and are often called "schnabel cars".

The cars lined up between the locomotive and the furnace are located on the supply trestle, where material for the furnace was brought and dropped into partitioned storage areas below the tracks. (In the photo, the rails of the supply tracks have been removed, and only the supporting beams remain in place.) These supply piles were transferred from below ground in a miniature railway that loaded material from the stock piles and moved it to a transfer point. Here the skip car for the charging hoist was filled before traveling to the top to be dumped into the furnace.

In order to understand the process and the layout of the furnace operation at Sloss, there are interpretive panels at various locations on the site. Here is a sample, which shows a cross section of the furnace, the supply trestle, and the hoist.

The material in the furnace became iron and was drawn off the bottom of the furnace, as was the slag or waste, although the slag came off the furnace at a higher level than the iron. In many areas these slag dumps resembled hills of candle drippings, and the dump tracks were extended on along the piles as they spread out. This material, when cooled could be used for various things, including coarse aggregate for road building as well as a soil supplement. At Sloss, the slag piles were located on site. Here the slag was allowed to cool, and then loaded with steam shovels, and removed or sold to make other products.

The molten iron would flow in troughs to the sand floor of the casting shed and the workers would divert the stream to the desired point in the sand. As the molten iron filled the molds for the bars, lined up in a row, along the trough, the workers thought that they looked like piglets suckling a sow. This is understood to be the source of the term "pig iron". In later years with the bottle car and the automated continuous casting machine this bit of folklore was lost, but apparently the name stuck.

|

|

|

The color photo, by the author, shows a view of Sloss City Furnace looking northeast from the 1st Avenue Viaduct. The furnace to the right is the western most furnace with its accompanying "stoves" in the center of the picture. The blower house is nearly hidden in the center behind the stoves. The black and white photo is taken from the Library of Congress archives, and was taken by Dorthea Lange, in June, 1936, from approximately the same location. Obviously the lens and format are different.

Study the photos carefully and notice that the blast furnace, casting shed, and sloping skip hoist are the same, for a reference point. Then, notice the sloping roof, among the stoves, which is the blower house. The square building on the left is another reference. Notice that the stoves are different, and there is an enclosure over the pipes in front of the stoves. Then, notice in the foreground that the concrete pits in the old photo have been removed. There is a steam shovel in one of the pits. These are the slag pits, and the shovel was used to move and load the slag when it had cooled. Today this shovel, or one like it, sits nearby, on the other side of the central complex.

Additional photos will be added from time to time, as I have time. Hope you enjoy them. The real fun is coming to Birmingham, and taking a tour of the furnace complex. Ya'll come, y'hear?

Visit the Sloss Furnace web site Red Mountain Ore Mine, Sloss. No. 2