Coke Ovens & By Products Plants

There are three basic ingredients to make iron and iron, in turn, is used to make steel.

The three basic ingredients are iron ore, limestone, and coke. The first two are natural raw materials, but coke is a by product of coal, when coal is heated under controlled circumstances. This heating occurs in a "coke oven". One of the unique things about the Birmingham District is that iron, coal and limestone occurred naturally in close proximity to each other. In fact, closer than any other place in the world.

Early coke making involved the use of beehive ovens, so

named because of their round dome shape. Later, these were consolidated

into rows, with stone sidewalls, called battery ovens, because many ovens could

be lined up along railroad sidings for loading and unloading. When coke

was made under these circumstances, the by products we generally lost or

wasted. Since coal is a hydrocarbon, there are many noxious but useful by

products that can be claimed as the coke is being made.

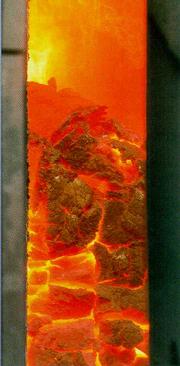

In the later 1800's there were European processes developed that produced coke, and captured the by products so that they could be used or sold. Birmingham developed at the same time as this technology, so in Birmingham we see the whole range of techniques and facilities used for coke making. The picture at the right (from AISI) shows an open modern coke oven at the end of the coke making cycle.

Today there are two large coke plants in Birmingham, Sloss and ABC or Alabama By Products Company. Both of these plants have been in operation for years. In fact, at Sloss, employees say that the fires burning today are the same fires that began burning in 1920 when the plant began production. That is, the fires never go out, and production is continuous.

In model railroading, there is a great model of these "modern" coke plants, at least the coke oven parts. This model is sold by Walthers and a picture of the model is shown here. The by product recovery plant is not part of the model, but could be easily adapted from other parts by "kit bashing" from oil storage and refinery parts. Walthers also sells models of beehive and battery ovens.

There is a great web site that provides diagrams of the coke making process provided by the AISI, American Iron and Steel Institute.

There are a lot of things to share about this topic in Birmingham, and some good resources on the internet. I will make an effort to tie some of this together in the following pages. (Under Construction)